Vacuum Conveying Division

Provides intelligent flow to materials

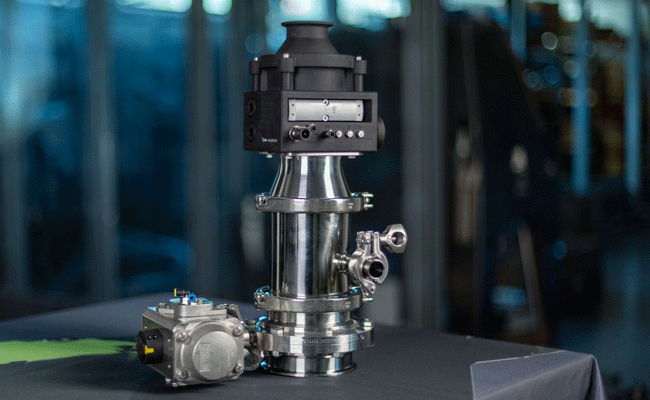

The Vacuum Conveying division of Piab Group provides powder handling solutions based on the cutting-edge vacuum conveyors that move powders, granules, and small parts from one process step to the other in a production line.

Benefits of Piab vacuum conveyors

Vacuum conveyors lead to a safer production environment for its users than other methods of powder transport. It is an ergonomic solution where the transported material is contained during the transportation process, avoiding cross-contamination, safeguarding product quality, replacing manual handling, and increasing employee safety at the same time.

Piab conveyors are highly efficient and reduce product loss, resulting in less waste.

Visit piab.com

Applications and compatibility

Materials with a wide range of bulk densities can be conveyed with specialized Piab vacuum conveyors, from flour and sugar, across desiccants and detergents, all the way to metal powders.

Piab vacuum conveyors are used across all continents, mainly in food, pharmaceuticals, chemicals, batteries, and additive manufacturing industries. The conveyor range of Piab has a modular design that is fully configurable. It covers a 3-56 l batch volume with up to 15t/hour material handling capacity. Piab vacuum conveyors can be assembled quickly based on the capacity, material characteristics, and other requirements of the user. They are easy to integrate into existing systems. They are compatible with a wide range of controls (from both Piab’s proprietary range and other controls available in the market). The modular design of Piab conveyors enables easy cleaning and supports scale-up in cases when production capacity requirements increase.

Our vacuum conveyors connect the dots in the production line – they are used in various stages of the manufacturing process, from the initial material handling to the final packaging stage. Applications include filling tablet presses, metal 3D printers, packaging machines with powders, reclaiming material, and filling or emptying from and to adjacent equipment such as a sieve, a dosing unit, a mixer, or a powder container.

Suitable for all automation needs

- Vacuum conveyors are available in 4 different automation levels.

- Standard systems handle materials with a basic function.

- Batch Volume Optimization allows for a better understanding of what happens in the conveyor body, avoids overfilling, and, thanks to a maximized capacity, leads to faster conveying.

- Piab vacuum conveyors equipped with Conveyor Cycle Optimization only require minimal setup.

- Auto-tuning is a fully automatic solution that optimizes the full system setup for extremely reduced time on material changeovers.

The product range

The Piab vacuum conveyor range consists of the pFLOW® family completed by compatible spare parts and accessories as well as adjacent machinery, like IB MPS sieving stations, for screening reclaimed and virgin metal powders in the additive industry.

Piab vacuum conveyors are made of stainless steel, which is 90-plus% recycled and sourced from the Nordics (except for China). Stainless steel is a durable, recyclable, and clean material that allows long product lifecycle.