We Evolve Automation

Let's automate a better world

At Piab Group, we develop smart automation solutions that empower industries to work more efficiently, sustainably, and safely. Our offering is built on cutting-edge vacuum technology - powered by compressed air or electricity - enabling intelligent gripping, lifting and moving. Each solution is tailored to meet the evolving needs of manufacturers and logistics providers around the world.

Scroll down to explore how we deliver value across industries and technologies.

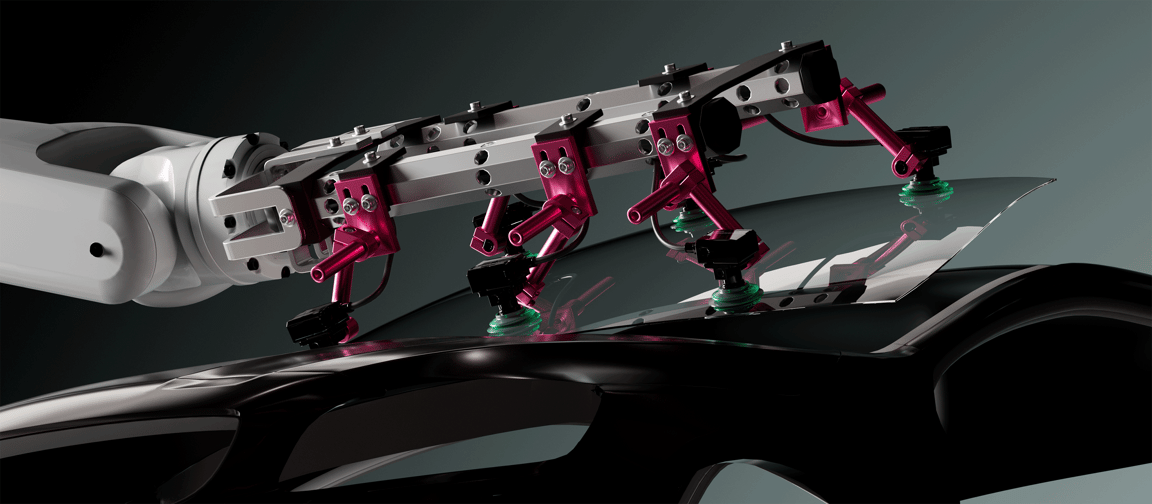

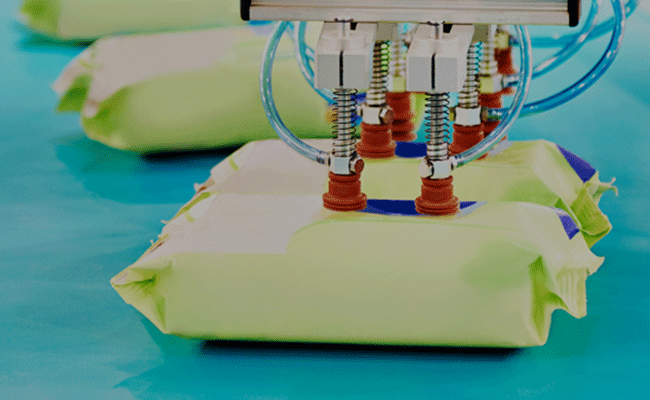

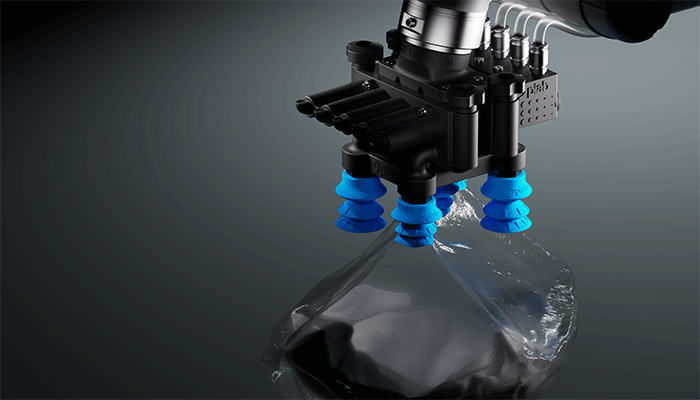

We give skills to robots & machines

Our Gripping Solutions include suction cups, soft grippers, vacuum generation and EOAT (End-of-Arm Tooling) systems for robots and various machine applications.

We give lifting power to humans

Our Lifting Solutions include vacuum lifters, crane systems, and ergonomic handling tools that support safe and efficient workflows.

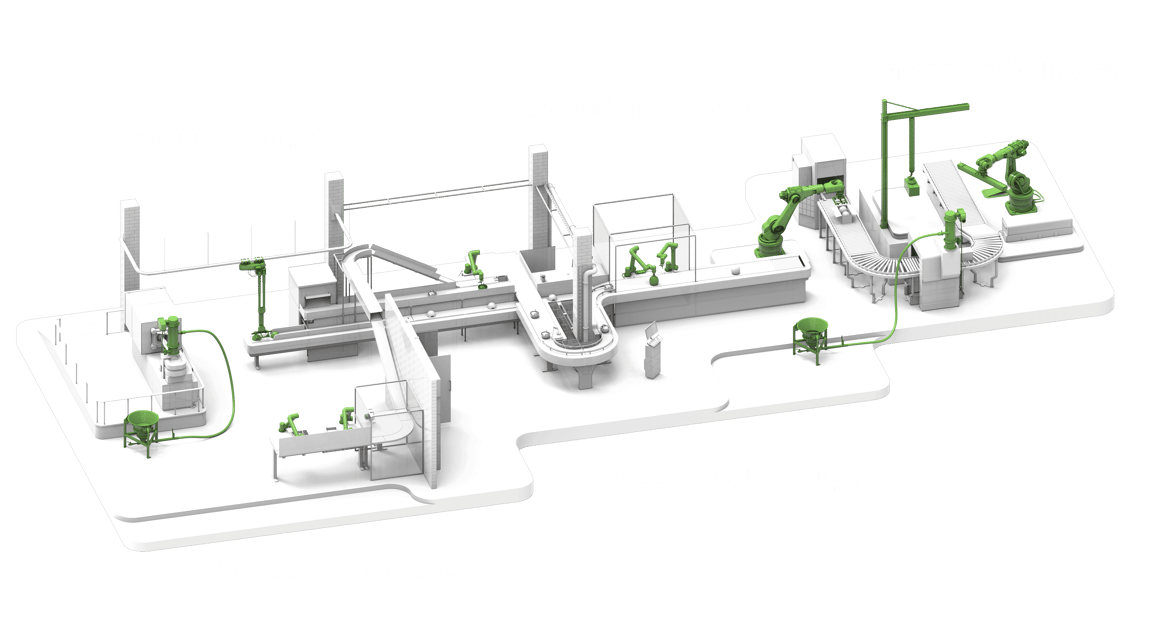

We provide intelligent flow to materials

Our Moving Solutions include enclosed systems for clean and efficient transport of powders, granules, and dry bulk materials.

Our products can be found almost everywhere in a production and assembly process. They are industry and segment-agnostic and can be used everywhere.

Industries we serve

We work across a wide spectrum of industries, each with unique demands, challenges, and opportunities. From high-speed production lines to precision handling in sensitive environments, our smart and adaptable solutions are engineered to meet the real-world needs of modern manufacturing and logistics. These industries guide how we tailor our technologies, from design to implementation, to deliver maximum impact.

Automotive

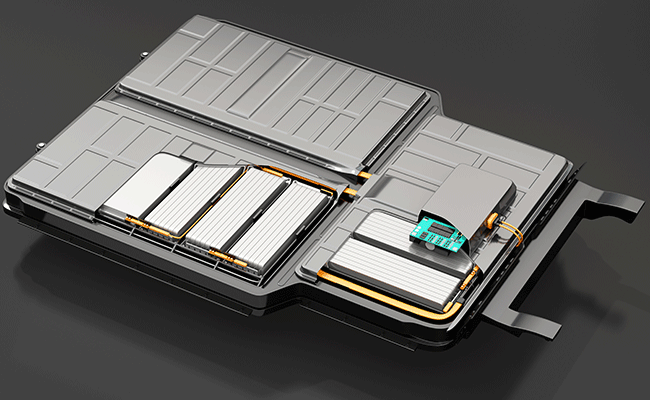

Battery

Chemical

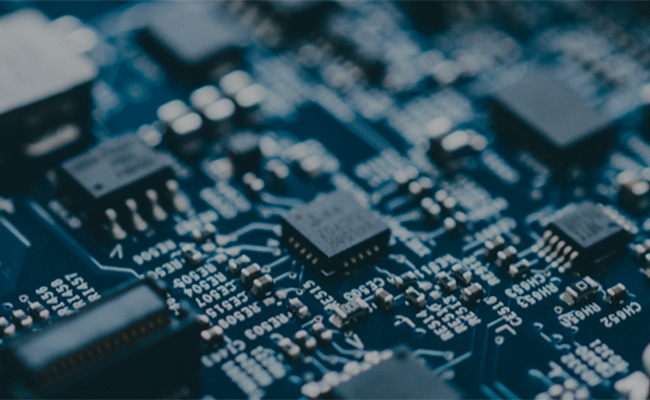

Electronics

FMCG

Food & Beverage

Logistics

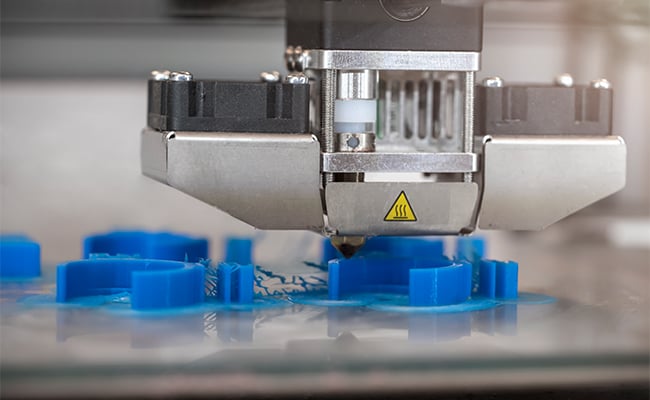

Metal Additive

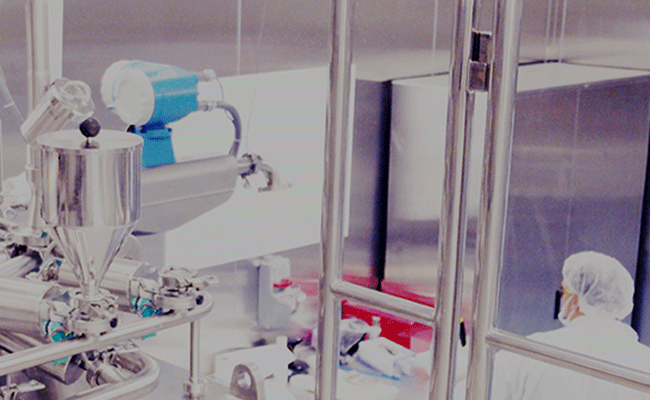

Pharma Automation

Plastics

Packaging

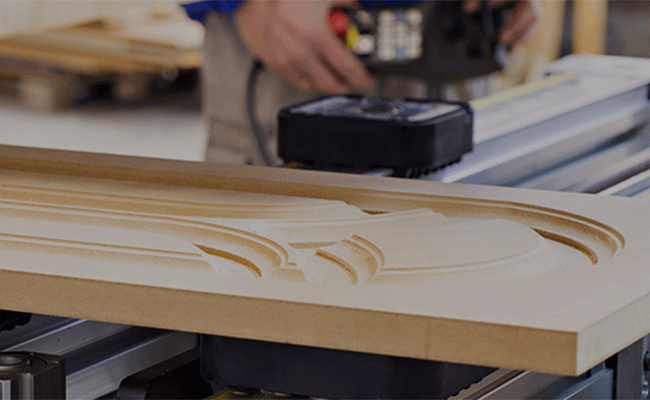

Wood

Our core technologies

Behind every Piab Group solution is a foundation of powerful and proven technology. All engineered for reliability, performance and sustainability.

Vacuum generation

Advanced air-driven ejectors and decentralized electric pumps deliver high performance, energy efficiency, and compact design. Built with sustainable materials, our systems feature smart energy-saving functions that maximize overall vacuum efficiency.

Lifting aids

Ergonomic vacuum lifters and trolleys designed to improve safety, reduce strain, and integrate seamlessly into workflows. These low-maintenance systems help increase productivity and support operator wellbeing.

Gripping

From suction cups and soft grippers to foam grippers and complex multi technology EOAT systems, we provide tailored solutions for high-performance part handling. Our gripping technologies serve a wide range of industries, including logistics, packaging, and wood, with sustainable options for a greener future.

Vacuum conveying

Hygienic, stainless-steel systems for the clean and safe transfer of powders and bulk materials. ATEX-certified and FDA-compliant for reliable, contamination-free conveying across sectors.

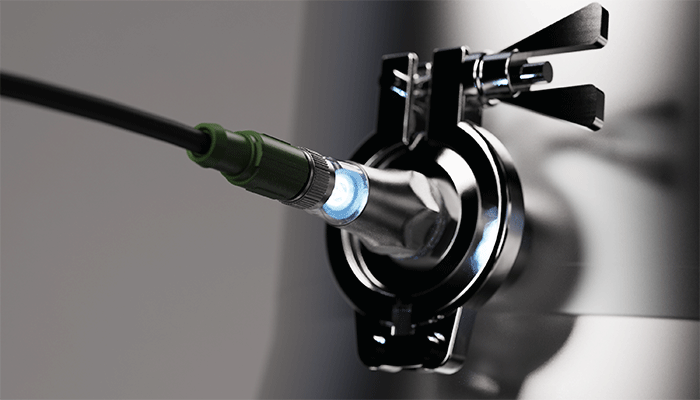

Sensors, actuators and control interfaces

Smart sensors, actuators, and control interfaces simplify setup and boost performance. Intelligent feedback enables predictive maintenance and helps maximize uptime in automated environments.

Certified for excellence and safety

Across our portfolio of brands, many of our products are certified to internationally recognized standards, ensuring quality, safety, and performance across industries and regions. These certifications are your assurance that Piab Group delivers safe, compliant, and reliable solutions, ready for the most demanding environments.

ISO 9000

Reflects our commitment to quality management and continuous improvement.

ATEX

Certified for use in explosive or hazardous environments, meeting stringent EU directives.

Additional standards

Depending on the product, our solutions also comply with CE marking (EU safety and health), and FDA (food and pharma applications).