Green Efficiency

At Piab Group, we are committed to being a catalyst in the fight against climate change. By leveraging our expertise in developing cutting-edge products and solutions, we enable new levels of resource efficiency. But our commitment goes beyond product innovation. We are also dedicated to running a CO₂-neutral business by reducing our energy consumption and contributing to a circular economy. Through these efforts, we believe we can pave the way toward a more sustainable future, demonstrating that environmental responsibility and business progress can go hand in hand.

Scope 1

Our car fleet accounts for 76% (?) of our Scope 1 CO₂ emissions. We are proudly dedicated to ecological responsibility and have committed to making our entire vehicle fleet 100% electric by 2030.

Scope 2

Most scope 2 emissions are accounted for using electricity globally at all our offices and manufacturing sites. We are actively working to transition to renewable electricity from grid, solar, and wind at all sites. Today, almost 50% of our electricity is renewable.

Scope 3

Our scope 3 emissions are generated in three categories: Upstream transportation, Use of Sold products, and Purchased Goods & Services. We are 100% committed to improving for the better, not only for us but for everyone in the value chain.

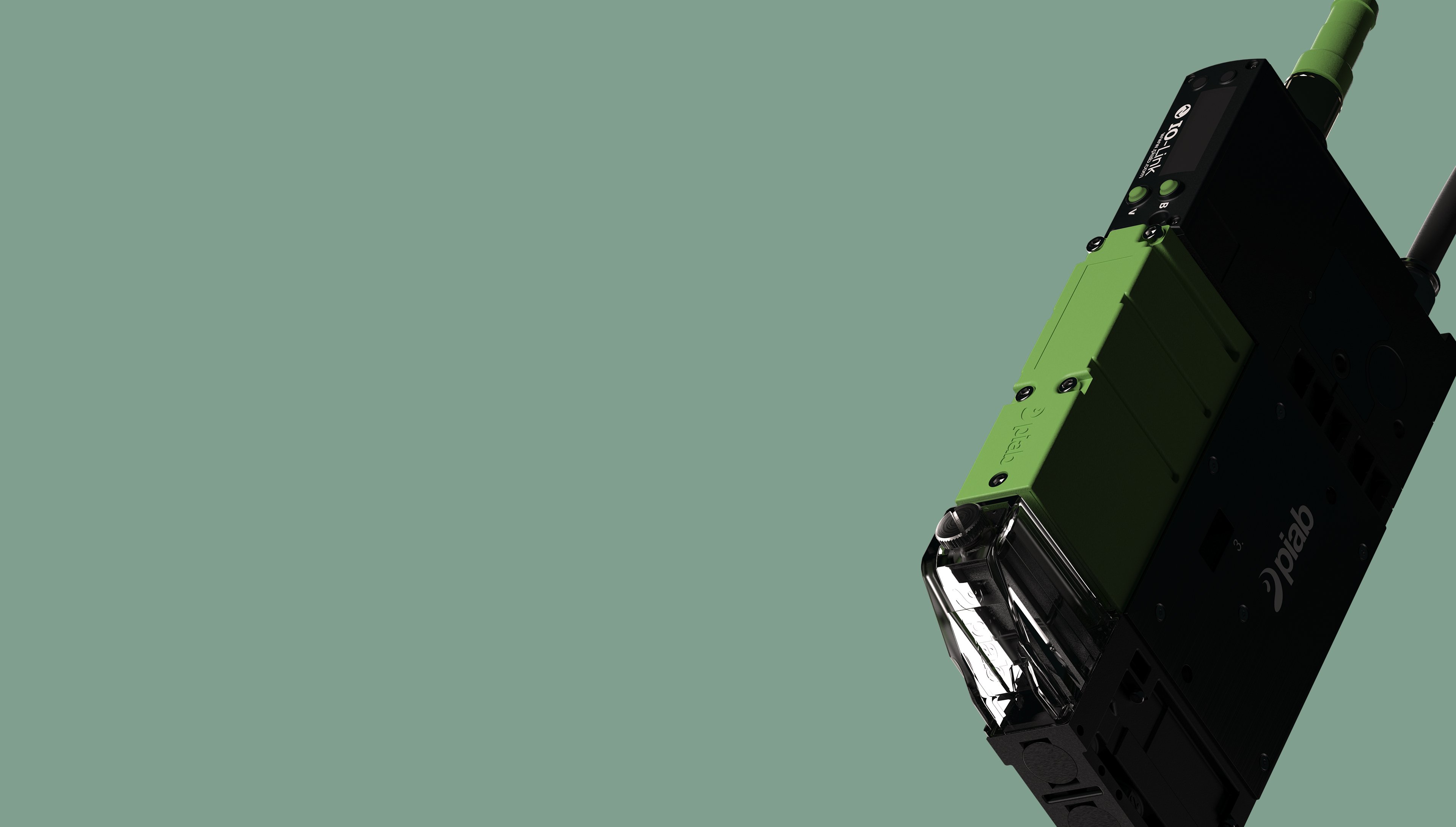

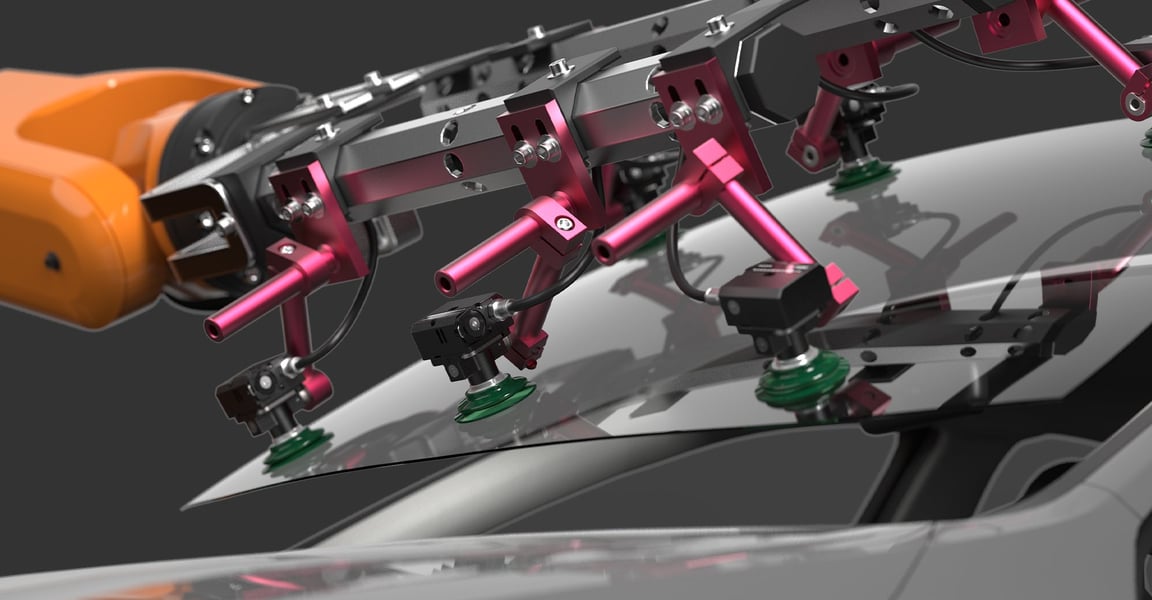

Energy saving functionality

Objectives for vacuum generation and release

- Reduce energy consumption by up to 95%, the ability to pick and place objects with the same gripping power using significantly lower energy consumption, equal to a saving of 50-100 tCO₂e*

- Autonomously Optimizing vacuum generation: Dynamically adjusting the capacity of the vacuum system to the application needs to reduce the energy consumption to a bare minimum

- Minimizing energy usage for object release: Use innovative release technologies to minimize energy consumption

- We´re designing vacuum gripping systems optimized to max the gripping power and minimize the energy waste

*Automotive body-shop in the US, 2024

Aluminum gantry system

Reduced CO₂ emissions with new aluminum gantry system

- 10-20% lighter profiles can reduce CO₂ emissions by 35 tons/year

- Stronger joint reduces scrap, leading to 19 tons/year in reduced CO₂ emissions

- Energy savings in manufacturing up to 40,000 kWh (no oven heating), plus 25,000 kWh (no cleaning system)

- Up to 20% faster installation due to no onsite drilling

Designed for circularity

Objectives for using a single material filter for improved circularity

- The all-new filter is crafted from recyclable polyethylene, using less material than our current range of filters, and consequently emits less CO₂

- Constructed from a single material, the filter is easily managed as waste

- It ensures maximum performance throughout its lifetime and can be washed repeatedly

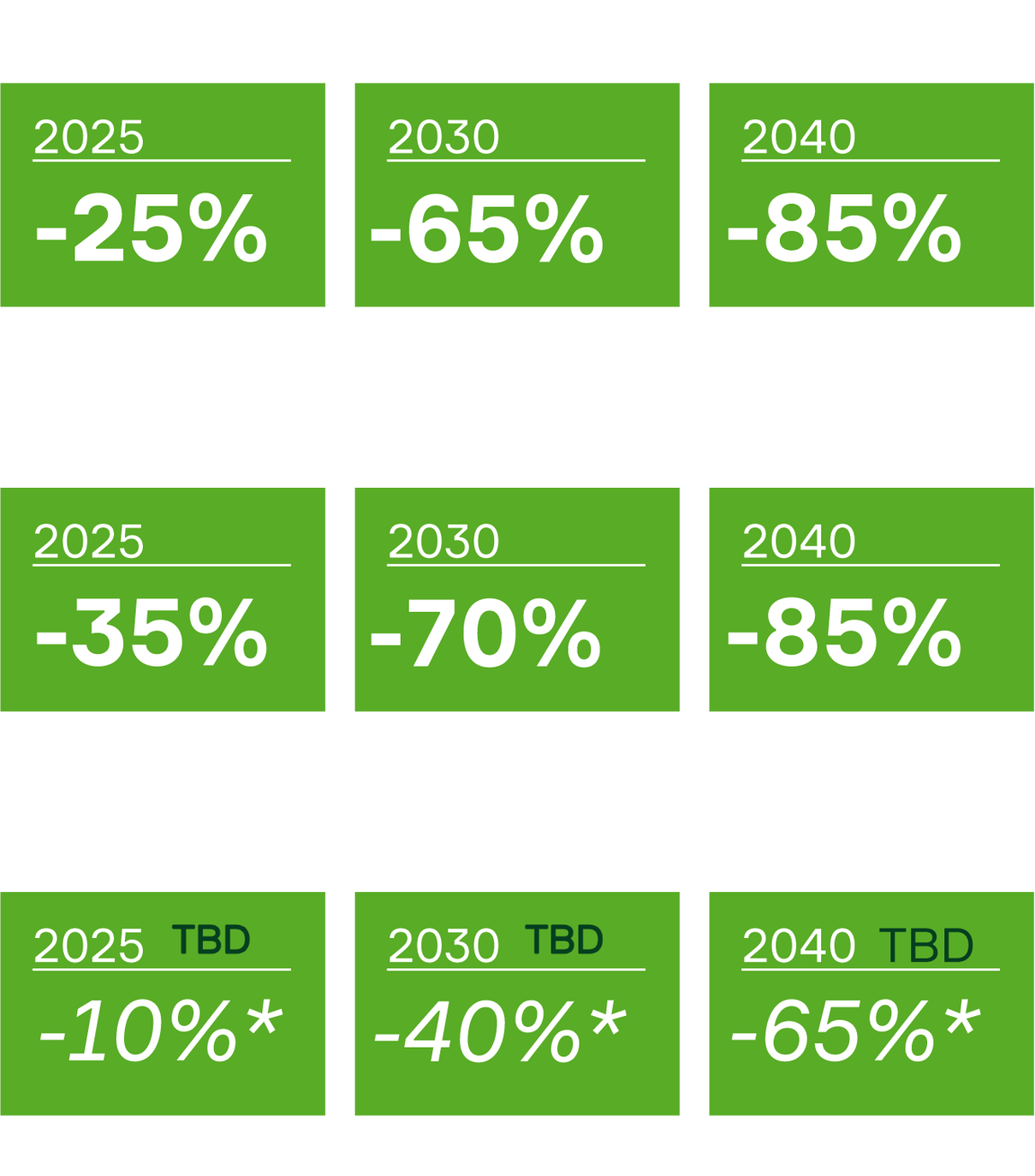

Piab Group CO₂-emission reduction targets

Three scopes are used to categorize a company’s direct, indirect and other associated carbon emissions. Within each scope, Piab Group performs regular assessments to define relevant reduction targets and measure our progress towards achieving them.